Tear Down Begins

Start date was Feb

22nd 2002 for tear down. Tear down was about 3 months. Probably an average of

20 hours a week worth of work, so about 300 hours to get the car torn down to

a shell and sent it out for blasting.

With any Car restoration

there are literally thousands of parts to inventory and track. I used digital

pictures to document all the original details. Hardware and small parts were put

in plastic bags and numbered. I used a spreadsheet to inventory all bags. Ended

up with about 450 Bags of parts.

With any Car restoration

there are literally thousands of parts to inventory and track. I used digital

pictures to document all the original details. Hardware and small parts were put

in plastic bags and numbered. I used a spreadsheet to inventory all bags. Ended

up with about 450 Bags of parts.

The interior was the

first to go. The car had very little of the original interior, however I documented

as much of the original interior as possible and saved everything. The rubber

weather stripping was completely rotten. Things move pretty quickly during the

tear down. It was about a 3 month process working mostly on weekends to strip

the car down to base components. Storage of parts was the biggest challenge, I

ended up with about 30 numbered boxes. I kept a manifest of the contence of each

box. All the original interior material and rubber was saved as reference when

reinstalling. Note the incorrect fuel pump on the trunk wall, This was a short

term fix to get the car going.

The interior was the

first to go. The car had very little of the original interior, however I documented

as much of the original interior as possible and saved everything. The rubber

weather stripping was completely rotten. Things move pretty quickly during the

tear down. It was about a 3 month process working mostly on weekends to strip

the car down to base components. Storage of parts was the biggest challenge, I

ended up with about 30 numbered boxes. I kept a manifest of the contence of each

box. All the original interior material and rubber was saved as reference when

reinstalling. Note the incorrect fuel pump on the trunk wall, This was a short

term fix to get the car going.

The chrome and all

exterior hardware was the next to go. All of this will be replaced or re plated.

The rear deck lid was in nice shape and however all of the glass was scratched

and will most likely not be used. The deck lid channel was rusted out as was the

trunk floor. Based on what I've seen, this is the most common area to rust on

FHCs. Fortunately the sheet metal is all available.

The chrome and all

exterior hardware was the next to go. All of this will be replaced or re plated.

The rear deck lid was in nice shape and however all of the glass was scratched

and will most likely not be used. The deck lid channel was rusted out as was the

trunk floor. Based on what I've seen, this is the most common area to rust on

FHCs. Fortunately the sheet metal is all available.

Dash stripping is pretty

much done here, and only the wiring harness remains. The harness will be replaced.

Various hack jobs had been done over the years to support radios etc. The Transmission

tunnel is dirty but in good shape as are the floor boards. I'll replace the

foot wells but the rest of the floor is solid with minimal rust or damage.

Dash stripping is pretty

much done here, and only the wiring harness remains. The harness will be replaced.

Various hack jobs had been done over the years to support radios etc. The Transmission

tunnel is dirty but in good shape as are the floor boards. I'll replace the

foot wells but the rest of the floor is solid with minimal rust or damage.

Here is a close up of the rear window frame. 40 years

of water have done wonders for the trim strip. Fortunately the metal under it

is in pretty good shape. Lead was loaded here as part of the roof seam, and

it helped protect the steel under this strip. Unfortunately this was not the

case with the truck tub and foot wells etc.

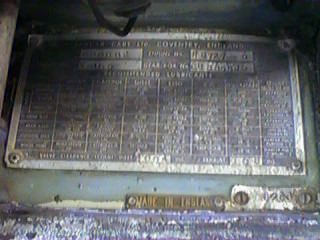

The serial number plate

is well faded. The car still bears its 1963 California registration tag and the

made in England tag. The engine and transmission numbers match except for the

head which was replaced. I found a NOS 3.8 Liter head which will be used in the

rebuild.

The serial number plate

is well faded. The car still bears its 1963 California registration tag and the

made in England tag. The engine and transmission numbers match except for the

head which was replaced. I found a NOS 3.8 Liter head which will be used in the

rebuild.

I'll need to find an original

Lucas generator eventually to replace this late model Ford alternator. Its pretty

clear in this picture just how tired the car really was. The original Caps for

the brake fluid tanks were replaced by plastic juice bottle lids. The heater box

is tired, and will need a good bead blasting.

I'll need to find an original

Lucas generator eventually to replace this late model Ford alternator. Its pretty

clear in this picture just how tired the car really was. The original Caps for

the brake fluid tanks were replaced by plastic juice bottle lids. The heater box

is tired, and will need a good bead blasting.

The original Lucas 2FP fuel pump

gave up the ghost many year ago and was full of crud. I bought a core and rebuilt this

pump. It appears the weak link in these is the brushes. A exhaustive search and discussion

on the XKE mail list turned up no rebuild kit for these, so I went to my local parts store

and found brushes which were close to original as possible. After some slight mods the

pump was put back together and is working like a champ.

The original Lucas 2FP fuel pump

gave up the ghost many year ago and was full of crud. I bought a core and rebuilt this

pump. It appears the weak link in these is the brushes. A exhaustive search and discussion

on the XKE mail list turned up no rebuild kit for these, so I went to my local parts store

and found brushes which were close to original as possible. After some slight mods the

pump was put back together and is working like a champ.

The Previous owner had

the radiator re cored, this radiator isn't correct. I will need to research the

correct 63 era radiator. The bonnet mounting frame is also tweaked and will be

replaced. along with the sub frame. I'll salvage the picture frame as it has the

original Serial number stamped into it.

The Previous owner had

the radiator re cored, this radiator isn't correct. I will need to research the

correct 63 era radiator. The bonnet mounting frame is also tweaked and will be

replaced. along with the sub frame. I'll salvage the picture frame as it has the

original Serial number stamped into it.

Dirt and grease are the

order of the day. The original metallic silver blue paint is pretty funky after

40 years on the road. The Sub frame looked good during tear down, it had only

minimal rust and no cracks, unfortunately the driver's side frame was bent inward

about 2-3 degrees so both sides will be replaced.

Dirt and grease are the

order of the day. The original metallic silver blue paint is pretty funky after

40 years on the road. The Sub frame looked good during tear down, it had only

minimal rust and no cracks, unfortunately the driver's side frame was bent inward

about 2-3 degrees so both sides will be replaced.

I took hundreds of shots

of all the detail areas and will compare to other S1 E-Types when putting the

car back together. I don't know how restorers got by before digital cameras. All

these parts will be sent to professionals for complete rebuild.

I took hundreds of shots

of all the detail areas and will compare to other S1 E-Types when putting the

car back together. I don't know how restorers got by before digital cameras. All

these parts will be sent to professionals for complete rebuild.

The under hood wiring harness

is trashed, many mods had been done to keep the car on the road. The entire mess

will be saved for reference, but a new harness will be a must. The battery box

area is well rusted, but fortunately nothing structural.

The under hood wiring harness

is trashed, many mods had been done to keep the car on the road. The entire mess

will be saved for reference, but a new harness will be a must. The battery box

area is well rusted, but fortunately nothing structural.

Don't think anyone ever

replaced the shocks on this car. The suspension appears to have been untouched

from the factory. I used several gallons of Chemtool to get these parts clean

and will send them out for plating as required. I was surprised overall at how

easily everything came apart compared to other cars I've worked on, California

cars just have an easy life verses those from northern states.

Engine

Pulling

Don't think anyone ever

replaced the shocks on this car. The suspension appears to have been untouched

from the factory. I used several gallons of Chemtool to get these parts clean

and will send them out for plating as required. I was surprised overall at how

easily everything came apart compared to other cars I've worked on, California

cars just have an easy life verses those from northern states.

Engine

Pulling