The brakes

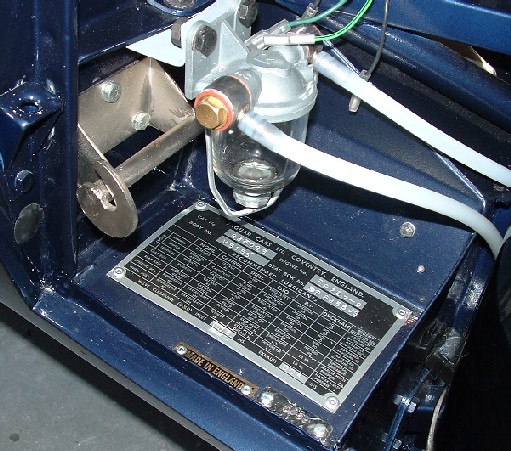

and clutch are all bled now and the battery is ready to go in. I found a

place online that sells modern replacement batteries that look like original

63 era Lucas lead acid batteries but are modern sealed maintenance free

units inside. This should save allot of grief. I've had normal lead acid

vintage replacement batteries in the past and they always leak acid. Acid

just kills the paint.

Not much

to say here but, hey its getting close now!

Here the

tail pipes and lights are in. I still need to put the back up light in but

that is fairly simple. I didn't remember to send out the license plate lamp

chrome bits when I had the last plating done so that is going to have to

wait.

Here is

the fuel tank after much toil. I had a heck of a time with this. First I

sent the tank out to a local radiator shop where they dipped it and coated

the inside, like a typical radiator shop they just shot black rattle can

on the outside right over the rust and dirt. So. I had to strip the outside

and repaint. After this was resolved, I discovered that the tank was a very

tight fit in the trunk. When I replaced the tub and most of the rear sheet

metal. a couple years ago, I had no templates or measurements to set the

back of the tub. So I found that it was about one inch to near the rear

wheel well. The result is that the tank was almost impossible to get in.

I managed to get it in after two weekends of cursing, but it is not a mistake

I'll ever make again. Next time I'm going to take some measurements before

hand from a known straight car. After getting the tank in I had to grind

out the mounting holes to get the bolts to line up. Lots of dirt and small

paint chips happened in this process in the tank area. I touched it up and

it isn't seen once the tank is in.

The rubber

molding went in without any issues. But you really need to be careful when

doing this and take your time. Its easy to damage paint wen working on these

kinds of things.

More rubber

molding. I made my lower door gap pretty close so had to make sure the weather

strip was glued down perfectly to the track. I used a razor blade to trim

the back side of the stripping to allow the door to shut flush.

Here is

the door gap so far, you can still see a slight ridge on the rear edge of

the door, I will continue to tinker with this as the car comes together.

Close enough for now.

Now the

door handle is on, i am still struggling with the lock mechanism but I'm

sure its just adjustment.

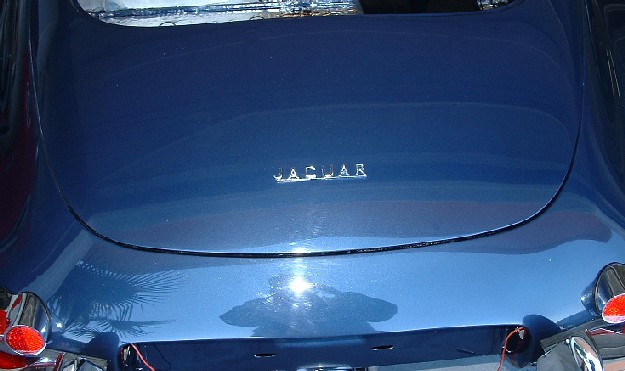

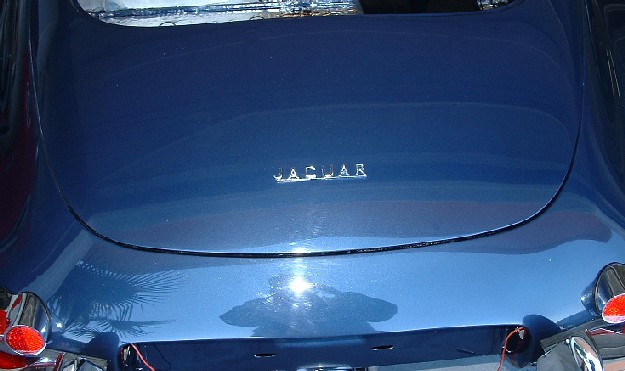

Simple

is so good! Here I have the Jaguar logo in place temporarily. I will take

it off and buff out the hatch one more time before clamping in it in for

good.

I went

ahead and put the fender wells in, I'm just about ready to start the car

now and hope I won't have to remove these again.

I have

the Driver's side Fender well in at this point, it has the horn relay mounted

on it and so I thought it would be good to get it in before I started the

car. Just need a battery now.

Battery

in and ready to go, I won't connect it until I'm sure the electrical system

is all correct.

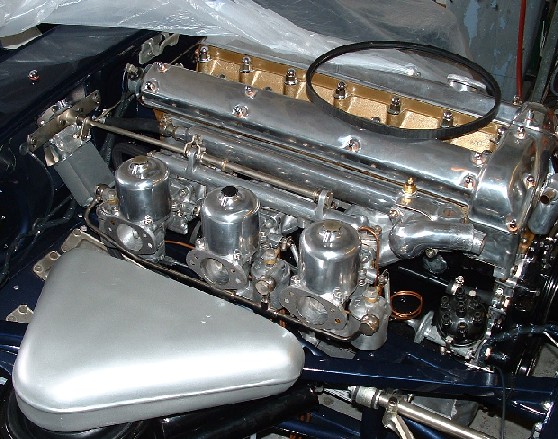

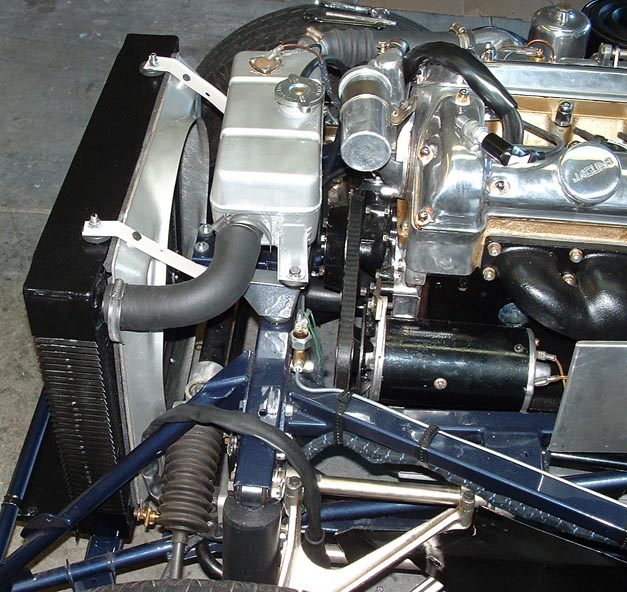

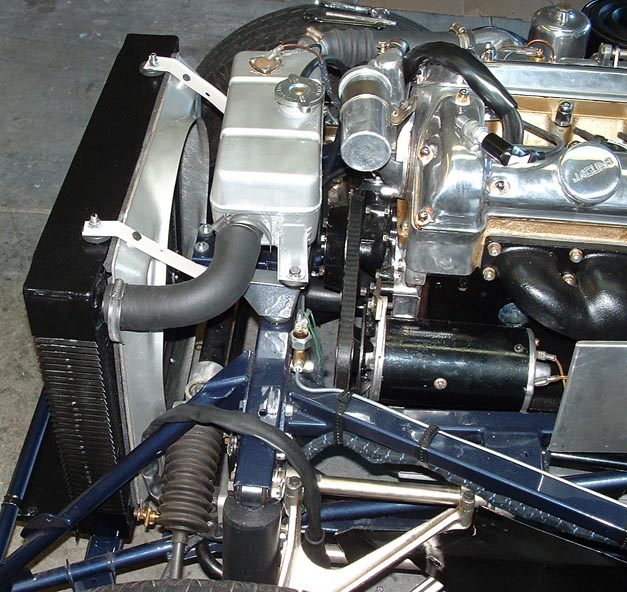

Here is

a fairly correct 3.8 Liter E-type aluminum radiator reproduction. I got

it from cool cat. Seems very well made. It isn't exactly like the originals,

but should be good enough for the judges.

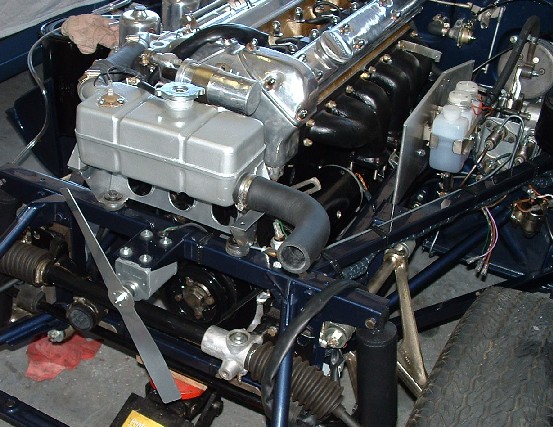

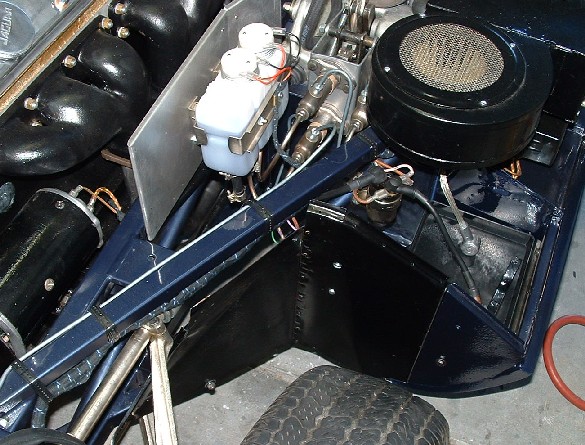

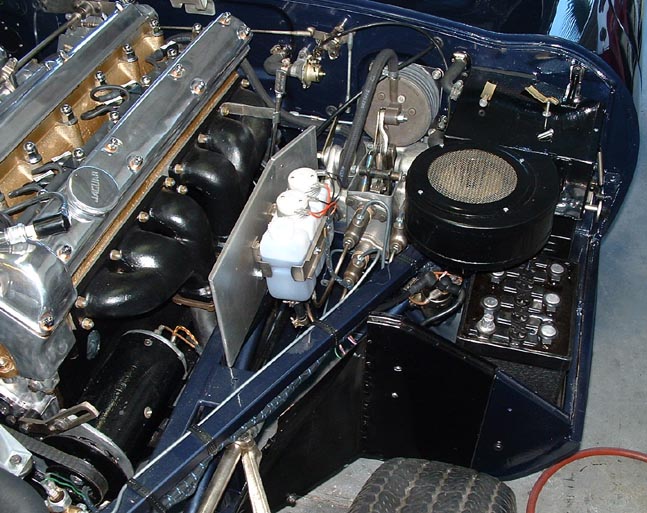

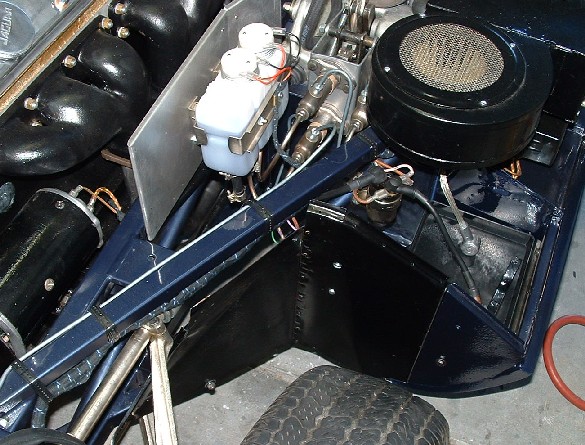

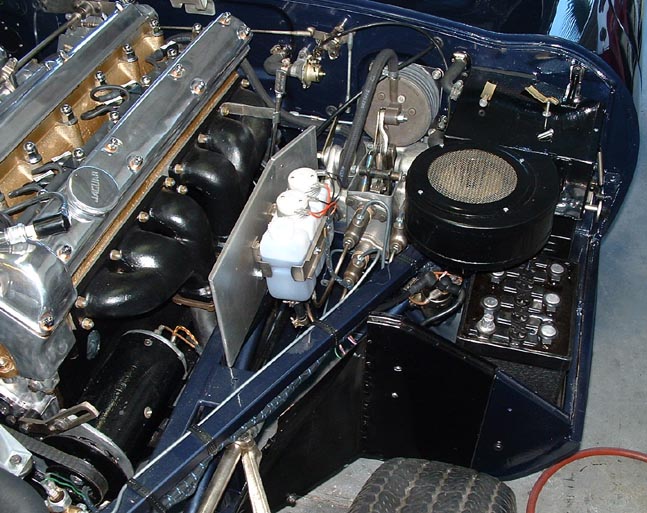

Getting

very close now. I have the radiator in and am trying to get spark. You can

see the number 6 spark plug out. I have dozens of small leaks in the cooling

system to debug but it won't be long now! As soon as I tried to turn the

car over with the starter, I found I had some major problem. It turned out,

that I had to pull the starter because it was dead shorted. I had put a

little plastic bushing in upside down and it was letting the power pin to

touch ground. Many will say its impossible to pull a starter on a 3.8 E-type

without pulling the engine. This is untrue. You need some special tools

but I got it out in a couple hours with an "S" wrench and a modified

5/8" socket. If you need more details email me.

Ready to

run! We have gas, We have spark, we have cooling, we have exhaust. We have

timing set, spark advance set. oil, brakes and clutch bled. Electrical system

mostly working.

There is

only one not so small problem so far. The transmission won't go into Neutral.

But more about this later, we are ready for fire in the hole!!!

Next up, Fire in the hole!