How to Electro Plate with Zinc!

Maybe I'm

insane, but when I started looking at all the hardware I would have to replace

or have re plated and the complexity and expense of packing up all the little

parts out and hoping nothing was lost etc, it became clear that home plating

would be a better solution if I could do it with the same level of quality

as the professional shops. I already have a bead cab and buffing wheel, so

only the electro plating system was required. This is a 3 gal Copy Cad kit

I bought from Caswell plating. It with a few additions allows for Silver Zinc,

Golden Zinc and Black oxide Zinc plating. In addition to the bucket in the

center, you'll need several other clean plastic buckets and a way to heat

water, some copper pipe for tank bars and brass or copper wire for hanging

parts. Plating is mildly dangerous as acid and other chemicals are required.

I wear heavy rubber gloves when working with the chemicals, and have an open

garage with good ventilation to avoid breathing concentrated fumes from the

plating tank. Zinc plating is not nearly as dangerous as Chrome or other heavy

metals, but still should be taken seriously. Ok enough of that safety talk.

I bought a cheap

crock pot my local hardware store ($23) to heat water. Its important to have hot

water for the parts cleaning system. The Plating tank is heated to around 90 degrees

F. with a fish tank heater. The crock pot heats water to about 190 Degrees F.

which is used for a soap solution for parts degreasing solutions. I use a second

fish tank heater to heat a muratic acid solution as well. You can also see some

of the other tools. hanger wire in Copper and Brass. A 1 Amp Power supply from

local electronics store, Digital Thermometer.

I bought a cheap

crock pot my local hardware store ($23) to heat water. Its important to have hot

water for the parts cleaning system. The Plating tank is heated to around 90 degrees

F. with a fish tank heater. The crock pot heats water to about 190 Degrees F.

which is used for a soap solution for parts degreasing solutions. I use a second

fish tank heater to heat a muratic acid solution as well. You can also see some

of the other tools. hanger wire in Copper and Brass. A 1 Amp Power supply from

local electronics store, Digital Thermometer.

Setup takes

several hours and I would recommend that if you do plating to save up at least

30-40 parts and do in a batch. this will take at least a day. Before starting

I bead blast all the parts twice to get all old plating or rust and visible

dirt off. This can be time consuming with small bolts; the threads are quite

difficult to get completely clean. The White bucket is clean water, The Blue

bucket is the Muratic acid solution, I mixed this about 20 to 1 with water.

20 parts water to 1 part acid very mild. I later freshened up the solution with

another part of acid when I notice the action slowing on new parts dipped. The

Caswell manuals are very good and go through

all the details.

After all the

parts were as clean as possible, I wired them up to the copper or brass wire

tank hanger wires. I tried to put smaller parts together on one string. The

more surface area the parts have the more power is required to plate. The manuals

go into this, and talk about using batteries and light bulbs to control current,

but really you need a fairly large DC power source between 1 and 12 volts at

up to 20 amps. Depends on what you are doing. a car battery and charger works

but a large Rheostat is needed, or other power soak are needed to control the

power. The best method for judging if you have the power right is to watch the

bubbles on the parts as they plate. To many bubbles and the plating will be

rough. Not enough and the plating comes out thin and dull gray. If you get parts

with a poor finish you can clean them up and plate again until the finish improves.

It takes practice but as with most things the more you do the better you get.

Here you can

see the tank Anode, Copper tank bar, and my power supply. I cut part of the

anode to make a hanger and wired the to plates together to make them easy to

connect to the power. The small DC supply I bought wasn't nearly enough power

to do larger parts and over heated smoking finally as I turned it to higher

settings to try and get larger parts to plate. I will replace this on the next

batch with a battery or some other DC supply. I checked at Fry's (my local electronics

store) and found a 20 amp DC supply designed for bench test. It has controls

for amps and volts and digital meters etc. about $200.

Here is the

cleaning tank, Caswell calls the powder

I mixed with water SP de greaser, but it feels and smells like laundry detergent

mixed with ammonia. I mix it with hot water and soak the clean parts in this

before dropping them into the acid tank. After plating is complete I soak the

parts in this to kill the acid from the plating tank. The parts I started with

were door locks and rear hatch hardware. I needed these parts to be clean and

rust free before I hung the door and hatch lid for finial fitting and block

sanding. These parts are mostly hidden when the car is complete so any sub standard

plating won't be visible in the finished car.

Here is the acid

tank at work parts bubbling away. I leave parts in this for around 30 minutes

and then dumped them into a fresh water holding tank. The Fresh water tank kills

the acid and slows down flash rust. Steel parts will flash rust in seconds after

being pulled out of this acid bath. You can actually watch the rust form on parts.

Even under water the parts start rusting while waiting to go into the plate tank.

If parts stay to long in either water or acid tank you need to blast them and

start over.

Here is the acid

tank at work parts bubbling away. I leave parts in this for around 30 minutes

and then dumped them into a fresh water holding tank. The Fresh water tank kills

the acid and slows down flash rust. Steel parts will flash rust in seconds after

being pulled out of this acid bath. You can actually watch the rust form on parts.

Even under water the parts start rusting while waiting to go into the plate tank.

If parts stay to long in either water or acid tank you need to blast them and

start over.

Here is the plating

tank at work. The part I'm plating is the tank bar. This was the first part I

plated. The manual says to start with your plating bar to purify the plating tank.

This gets any foreign metal onto a part that doesn't matter and keeps your plating

bar from corroding later. Copper turns green very quickly after coming in contact

with acid and doesn't conduct. Notice the air pipe in the tank. This is a fish

tank air pump and hose with a gang valve to control. It is used to agitate the

plating solution while plating keeping bubbles from forming on the part. Bubbles

which stick on the part can lead to a poor finish if they are aren't knocked off

periodically. In the future I think I'll find a better solution for this. Possibly

attach a vibrator t the tank bar. The air hose is hard to keep under water and

near the part. The other solution to this problem is just to move the part by

hand as the plating is in process.

Here is the plating

tank at work. The part I'm plating is the tank bar. This was the first part I

plated. The manual says to start with your plating bar to purify the plating tank.

This gets any foreign metal onto a part that doesn't matter and keeps your plating

bar from corroding later. Copper turns green very quickly after coming in contact

with acid and doesn't conduct. Notice the air pipe in the tank. This is a fish

tank air pump and hose with a gang valve to control. It is used to agitate the

plating solution while plating keeping bubbles from forming on the part. Bubbles

which stick on the part can lead to a poor finish if they are aren't knocked off

periodically. In the future I think I'll find a better solution for this. Possibly

attach a vibrator t the tank bar. The air hose is hard to keep under water and

near the part. The other solution to this problem is just to move the part by

hand as the plating is in process.

Here are the

first parts done with the system. Not bad but could get better. The two pipes

at the front left are sections of copper pipe I used for tests. The rear parts

were plated in two batches the Spring as a batch and the brackets as a second

batch. As soon as the parts came out of the plating tank they went back into

the degreasing tank to kill the acid and then I cut the wires. Avoid touching

the parts until the dry and cool off. The acid and oil on your skin will leave

black smudges.

Larger parts like

these door latches were plated whole. I was worried that the mechanics wouldn't

work after plating if I didn't completely tear them down. This was not the case.

These latches worked just fine after plating. The power supply I had wasn't powerful

enough to plate such large parts so even though I left the parts in the tank for

30 minutes or more they came out with a grayish tint in some areas. I helped correct

this by flash dipping half of the part at a time for a few seconds. But still

had some gray in the middle around the springs etc.

Larger parts like

these door latches were plated whole. I was worried that the mechanics wouldn't

work after plating if I didn't completely tear them down. This was not the case.

These latches worked just fine after plating. The power supply I had wasn't powerful

enough to plate such large parts so even though I left the parts in the tank for

30 minutes or more they came out with a grayish tint in some areas. I helped correct

this by flash dipping half of the part at a time for a few seconds. But still

had some gray in the middle around the springs etc.

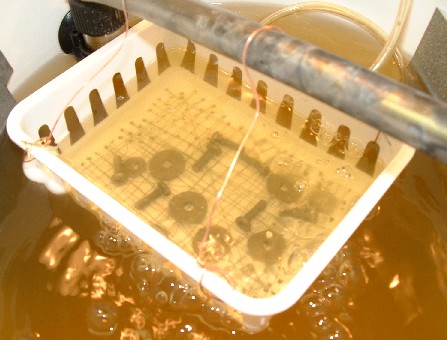

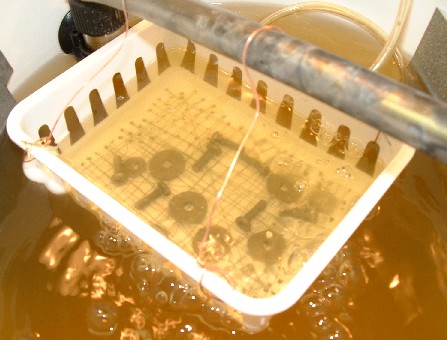

To quickly

plate small nuts and bolts I made this plating basket out of copper wire threaded

through holes in the bottom of this $.99 plastic basket from the hardware store.

The parts are just tossed into the basket and current flows through the copper

hangers. The parts make contact with the wire on the bottom. Occasional shaking

of the basket helps avoid any marks on the parts from the wires. My power supply

was a little weak but after some parts were removed it worked perfectly. With

a larger supply I could do several dozen parts at a time with this. setup. Saves

allot of time. This idea came from the very complete Caswell plating manual.

So far I have been really impressed with how easy plating is once you get setup.

Its not something I'd recommend unless you have large quantities of parts. The

setup time is several hours and the total investment could be $200-$500 depending

on how serious you get. The kit and accessories was about $250. The parts from

the hardware store were $50. If I go with a high end Power supply its another

$200. Still I'd guess it pays for its self after 2-3 batches of parts. If I

avoid loosing 1 hard to find part it will be worth what I paid. Later in the

restoration I may get a Nickel plating kit for all the suspension parts. Will

need at least a 5 gallon tank for this.

Block

Sanding and Sanding, and Sanding!